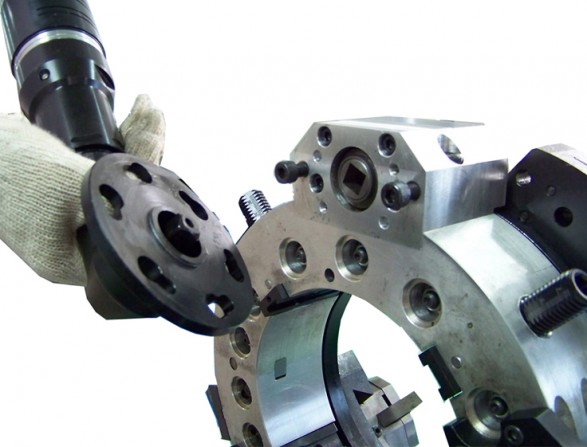

Heavy Duty Pipe Cutting and Beveling Machine

LEFON Heavy Duty Pipe Cutting and Beveling Machine is portable, designed to use in both workshop and on-site. This split frame clamshells is heavy duty, specially intended for heavy wall pipes with high wall-thickness in heavy duty applications. This portable pipe lathes use cold cutting principle that eliminates any heat affected zone. The machine split frame is made from aluminum which is extremely low weight for easy handling and lifting and are versatile in application and can perform many operations. The machine provides a fast metal removal rate and high working speed which presents the economical manufacturing solution.

- Cutting off pipes

- Simultaneous cutting and beveling

- Weld Preparation on the pipe end

- Inside-turning of pipe ends

- Flange facing, or Flange Repairing on-site