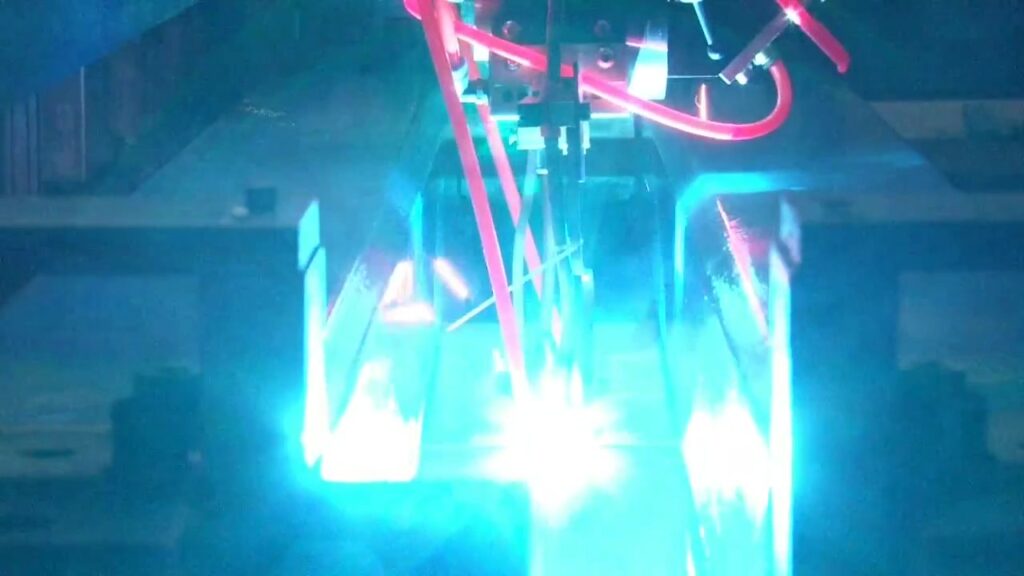

Laser Welding Machine

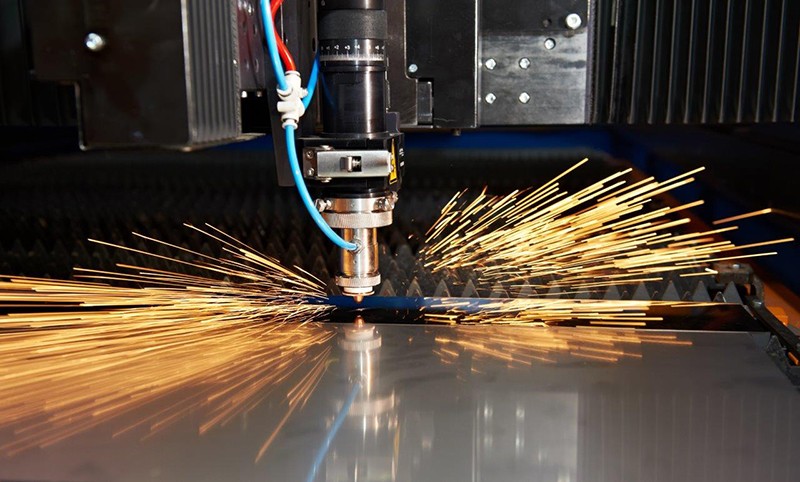

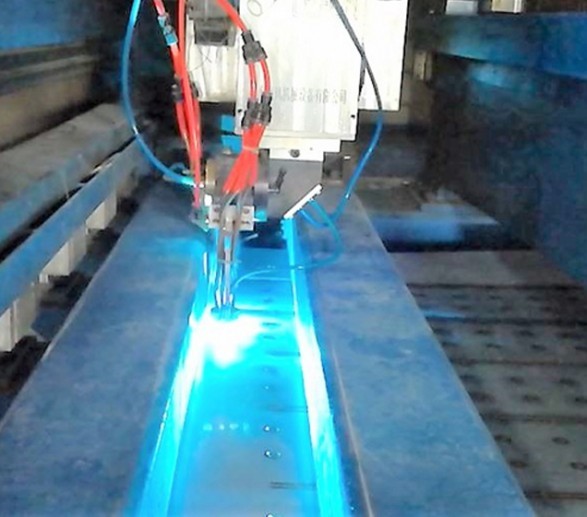

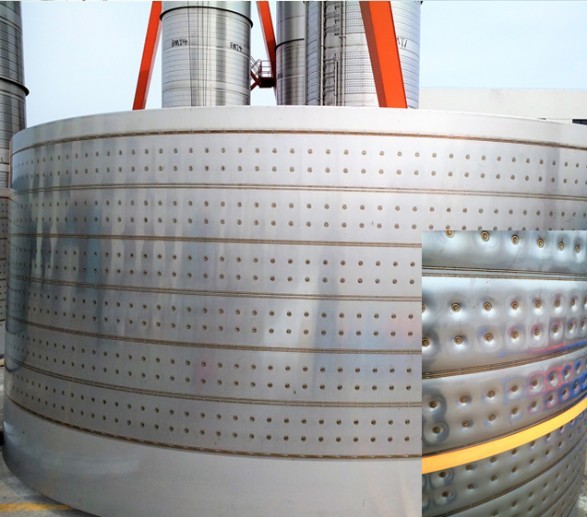

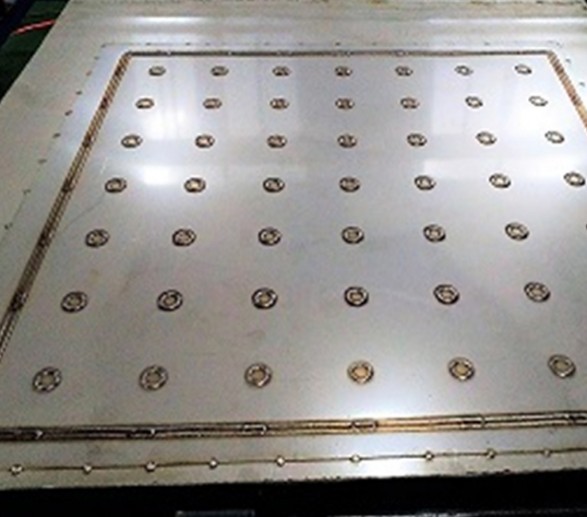

LEFON provides the latest Laser Plate Welding technology. For vessels needs to be heated or cooled, there are several types of heat transfer method applied to sidewall or bottom. The laser welded heat transfer jacket is one of the latest technology that is ASME certified. The laser welded dimple jacket is a sheet of metal which has a uniform array of depressions or dimples pressed into the metal by the latest laser welding technology, and then inflated to form flow pass. LEFON develops its own in-house world class laser welding machine.